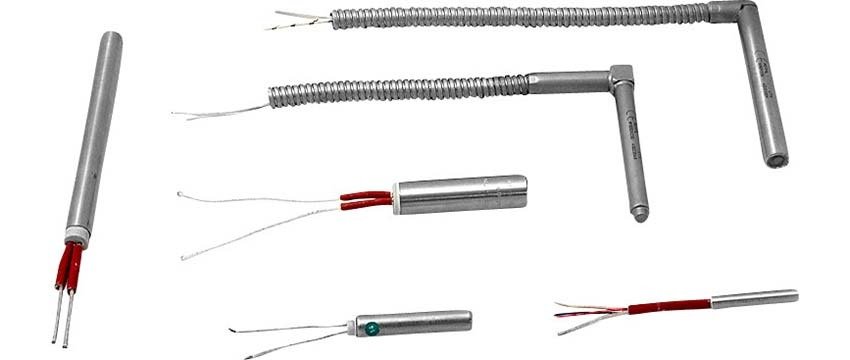

High and Low Density Cartridge Heaters

HIGH DENSITY CARTRIDGE HEATERS

Perfect Heaters High Density Cartridge Heater can be considered “Component Heaters” that are used to heat up many different applications. Primarily used in moulds, dies & sealing bars, this Cartridge Heating Element fit snug inside a cavity and helps heat solids by reaching high temperatures. High Density Cartridge Heater has the versatility of being able to carry thermocouple inside to help control temperatures of the heater more accurately. Various diameters allow for the Cartridge Heating Element to be used in any cavity and can be custom designed with any cold section. Lead wires extend from the end to your controls.

High Density Cartridge Heater distinguishes itself by its high compression and therefore especially efficient heat emission. That’s why such Cartridge Heating Element is produced with a ground surface for a H7 fit.

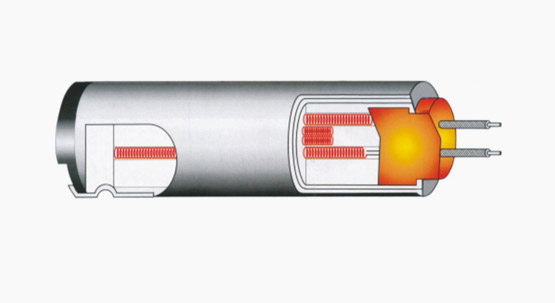

Construction

The construction of High Density Cartridge Heater positions a nickel-chrome resistance wire precision wound around a magnesium oxide core. It is inserted into a Stainless or Incoloy tube locating the resistance wire close to the sheath. The core is centrally positioned within the tube and filled with magnesium oxide powder. Nickel pins pass through the centre of the core making contact with the resistance wire at both ends. The whole assembly is highly compacted by a swaging operation and thus ensuring excellent heat transfer to the external sheath. One end of the heater is closed with a welded metal end-disc and wire leads exit at the opposite end which is typically closed with a lava seal. A variety of wire leads and lead protection options are available. The Cartridge Heating Element can be supplied with internal thermocouples, mounting fittings and many other options.

LOW & MEDIUM DENSITY CARTRIDGE HEATERS

Anupam Heaters Low & Medium Density Cartridge Heater is developed for heating applications not requiring high watt densities and sheath temperatures not exceeding 300°C. These Cartridge Heating Elements are designed in maximum watt densities of 30 to 45 watts per square inch depending on applications. Such a Cartridge Heating Elements of various sheath diameters can be used in any assembly, equipment or machine.

The Low & Medium Density Cartridge Heater can be absolutely customized to suit customer’s needs. Such Cartridge Heating Elements can be an economical option for customers not requiring high process temperatures. Cartridge Heating Elements are designed & calibrated perfectly to ensure that optimum conductivity between the resistance coil and the Cartridge Heater is achieved.

Construction

The Low & Medium Density Cartridge Heater design consists of a helically wound resistance coil made from nickel-chrome wire, evenly stretched and strung through holes in a round ceramic insulator. The element assembly is inserted into a Chrome Nickel Steel. This alloy provides the best combination of physical strength and resistance to heat oxidation up to 450°C.

Specially selected grain size and high purity magnesium oxide is used to fill all remaining space inside the ceramic insulator to increase thermal conductivity, dielectric strength, and provide longer operating life of the Cartridge Heater.