Infrared Heater

SHORTWAVE INFRARED HEATERS

Short wave quartz infrared heaters are used in various industrial applications. It contains tungsten filament, helically wound, encased in quartz envelope. Tungsten as resistive element is capable of generating temperature in excess of 2750° C. Its response time is very rapid in 1 second it emits over 90% of IR energy. It is by products free & pollution free. Heat focus is very accurate due to compact and narrow diameter of IR tubes. Short wave IR element has maximum heating rate of 200W/inch.

The quartz envelope allows transmission of IR energy and protecting the filament from convective cooling and corrosion. Addition of small percentage of halogen gas in it not only increases life of emitter but also protects blackening of tube and depreciation on infrared energy. The rated life of short wave infrared heater is around 5000 Hrs

Shortwave Infrared Heaters – Off Condition

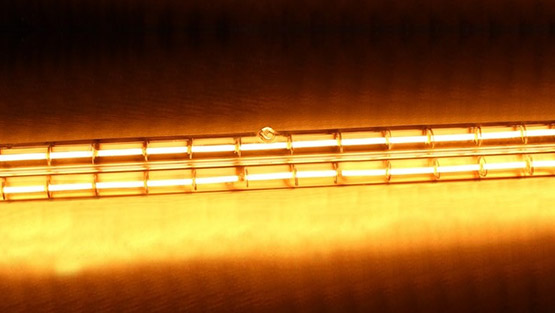

Shortwave Infrared Heaters – On Condition

Twin Tube Shortwave Infrared Heaters – Off Condition

Twin Tube Shortwave Infrared Heaters – On Condition

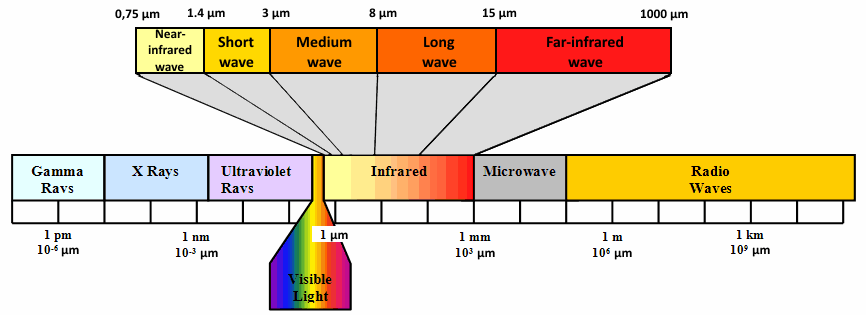

Short Wave Infrared Heater transmits heat in the form of electromagnetic waves at a velocity of approximately 3,00,000 Km/Sec i.e., at the speed of light.

These lamps are not only the fastest in transmitting heat but are most suitable for specific applications involving vacuum technology and dust free (clean room) conditions.

Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on products. Short Wave Infrared heaters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts.

FEATURES

- Shortwave Infrared Heater is a high efficiency heating radiator that can heat up to 900 °C and cool down in seconds. It is made of high purity of quartz tube and Tungsten wire, filling with halogen gases inside the tube to protect tungsten wire and avoid filament oxidation when working

- The emitted radiation of the lamps is much more effective than other heat transmission methods such as convection or conduction heating. Objects or their surfaces can be heated up from rather distant light source even through a glass window. Instant Radiation from the Lamp allows Fast & Flexible Thermal Processes

- The color temperature of shortwave quartz infrared heater is around 2400 to 2500°K.The IR wavelength of the of the Shortwave Infrared Heaters radiation emission is between 1 to 2 μ

- Available in different variations from customized Heating Lengths, Power, End Connections, Reflector Coatings and Shapes as well

MEDIUM WAVE QUARTZ INFRARED HEATERS

Medium Wave Quartz Infrared Heaters are excellent for surface heating and for drying coatings paint, dyes, lacquers, adhesives and in the processing of plastic sheet and films. They are available in Clear or Opaque Quartz Tube with gold or ceramic reflective coatings that focus the emitted energy onto the substrate.

The filament temperature of a medium wave emitter is from 850°F and 2150°F (454°C – 1177°C). The majority of energy generated by the medium wave lamps is in the range of the electromagnetic spectrum between 2-4 microns.

Medium wave emissions do not penetrate as deep into substrates as shortwave. The emissions are readily absorbed by water films, plastics and many solvents.

Medium Wave Quartz Infrared Heaters are slower in response to changes in process requirement as compared to the short-wavelength lamps and are slower to heat up and cool down.

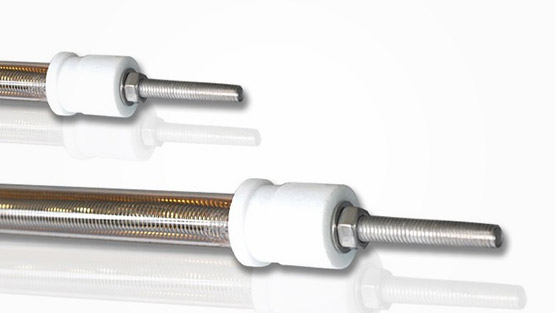

Because of their long life, medium wave quartz infrared heaters perform extremely well in continuous processes. Medium wave infrared heaters are sold as individual heat sources or wired together in multiple emitter cassettes also known as IR Modules. The Standard End Connection in the Medium Wave Quartz Infrared Heater is the Screw Connection with Ceramic Cap to Protect the Terminals.

Medium wave Quartz Infrared Heaters consist of a quartz tube with a nickel chromium alloy coiled filament. Perfect medium-wave quartz infrared heaters typically come in Diameters of 8 mm, 10 mm, 12 mm, 15 mm for Single Tube configurations or with 11 x 23 mm & 15 x 33 mm for Twin Tube configurations. The Lengths of the Medium Wave Quartz Infrared Heaters can vary from 300 mm to 1500 mm as per customers design and specifications. Standard medium wave emitters are not filled with any gases and are not sealed.

The Medium Wave Quartz Infrared Heaters are to be mounted in Horizontal Position only. Mounting support should be located on Non Heating ends.

Short wave quartz infrared heaters are used in various industrial applications. It contains tungsten filament, helically wound, encased in quartz envelope. Tungsten as resistive element is capable of generating temperature in excess of 2750° C. Its response time is very rapid in 1 second it emits over 90% of IR energy. It is by products free & pollution free. Heat focus is very accurate due to compact and narrow diameter of IR tubes. Short wave IR element has maximum heating rate of 200W/inch.

The quartz envelope allows transmission of IR energy and protecting the filament from convective cooling and corrosion. Addition of small percentage of halogen gas in it not only increases life of emitter but also protects blackening of tube and depreciation on infrared energy. The rated life of short wave infrared heater is around 5000 Hrs

Medium Wave Infrared Heaters – On Condition

Twin Tube Medium Wave Infrared Heaters

Medium Wave Infrared Heaters

Medium Wave Quartz Heating Module

CERAMIC INFRARED HEATERS

Ceramic infrared heat elements are efficient, robust heaters which provide long wave infrared radiation. The ceramic heaters and infrared heaters are used in a diverse range of industrial and engineering applications such as thermoforming heaters, packaging and as heaters for paint curing, printing and drying. They are also used very effectively in infrared outdoor heaters and infrared saunas. Ceramic elements produced by Anupam include ceramic trough elements, ceramic hollow elements, ceramic flat elements, and can be customized as per drawings.

Ceramic elements operate in the temperature of 300°C to 700°C (572°F – 1292°F) producing infrared wavelengths in the 2 – 10 micron range. Most plastics and many other materials absorb infrared best in this range, which makes the ceramic heater the most popular infrared radiant emitter on the market. A range of aluminized steel reflectors are also available to ensure the maximum amount of infrared radiation is reflected forward to the target area.

The element wire of Ceramic Infrared Heater is embedded in glazed refractory which protects the wire from atmosphere to get longer life. In normal operating condition the life of the heater for most application would be well in excess of 10,000 hrs of 80% power. These are available with built in J or K Type Thermocouple or without Thermocouple variants in Yellow, White & Black colors.

Housing For Single Ceramic Infrared Heaters

Housing For Connecting Multiple Ceramic Infrared Heaters In Series